TPU-Aero

Product Description

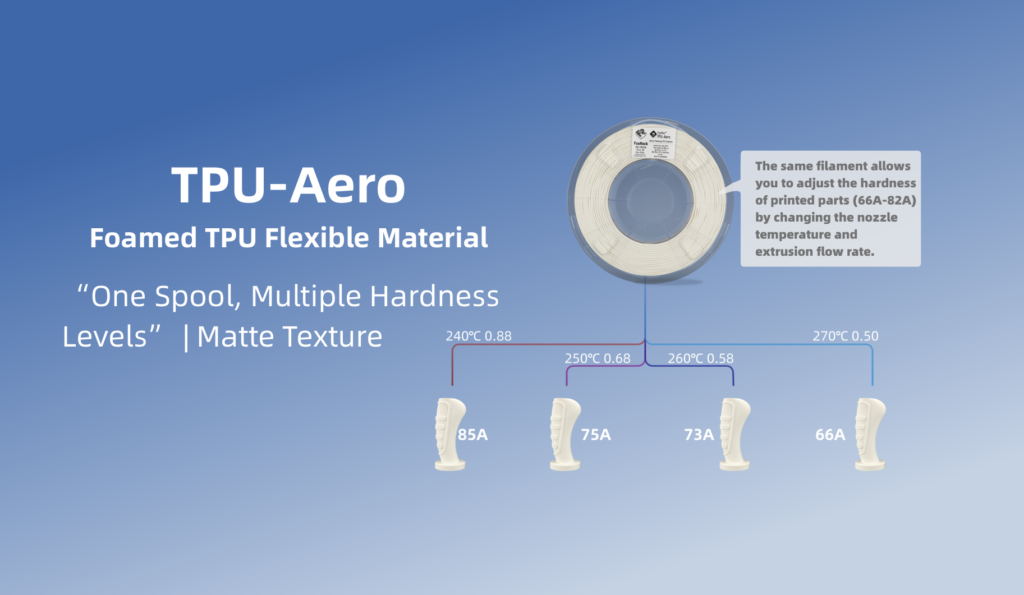

FusFlex™ TPU-Aero is a medium-hardness, active foaming flexible material specifically developed for FFF printing technology. By controlling the printing temperature, different extrusion foaming ratios can be achieved, resulting in varying weight reduction and softness effects. The surface hardness of FusFlex™ TPU-Aero printed parts can be controlled between 65A and 85A. At the maximum foaming rate, FusFlex™ TPU-Aero can reduce weight by 50% compared to ordinary TPU materials, with the printed surface exhibiting an excellent fabric-like texture.

Material Properties

Property | Testing method | Typical value |

Filament Density | ISO 1183 | 1.15 g/cm³ |

Melt index | 190°C,2.16kg | 8 |

Specimens print temperature | 240°C | 250°C | 260°C | 270°C | |

Flow ratio | 0.88 | 0.68 | 0.58 | 0.50 | |

Print parts density | ISO 845 | 0.93 g/cm³ | 0.74 g/cm³ | 0.62 g/cm³ | 0.54 g/cm³ |

Vicat softening temperature | ISO 306 | 78.8°C | 70.4°C | 61.8°C | 50.3°C |

Hardness | ISO 7619 | 82A | 75A | 72A | 66A |

Tensile yield strength (X-Y) |

ISO 527 | 5.98±0.10 MPa | 4.23±0.04 MPa | 3.22±0.05 MPa | 3.59±0.11 MPa |

Tensile breaking strength (X-Y) | 9.80±0.42 MPa | 6.81±0.11 MPa | 4.77±0.16 MPa | 3.59±0.11 MPa | |

elongation at break (X-Y) | 598.69±72.20 % | 576.27±8.48 % | 520.54±32.31 % | 452.13±19.40 % | |

Specimens printed under the following conditions: Nozzle size 0.4mm,Bed temp 45°C, Print speed 60mm/s, Infill 100%, Infill angle ±45°

Recommended printing conditions

Nozzle temperature | 230-270°C |

Recommended nozzle diameter | 0.4mm-0.8mm |

Recommended build surface | Glass, PC Film or Steel Plate with coating PVP glue |

Build plate temperature | 30-45°C |

Cooling fan speed | On |

Print speed | <150 mm/s |

Retraction distance | 0mm or Off |

Printing Tips:

- TPU materials are prone to absorb moisture when exposed to air. It is recommended to place the FusFlex™ TPU-Aero filament into a dry box (humidity controlled below 15%) immediately after opening the vacuum aluminum foil packaging. Unused filament should be sealed back in the original aluminum foil packaging.

- For FusFlex™ TPU-Aero filament that has been exposed to air for a long time, it is recommended to dry the filament in an oven at 70-80°C for 4-6 hours before printing to avoid issues such as bubbles, holes, or stringing caused by moisture.

- Due to the continuous expansion of foaming materials in the hot end chamber, leakage is inevitable during travel movement. Even adjusting retraction distance and speed cannot improve this. It is recommended to disable retraction in the slicing software, print only one model at a time, or use the print-by-part function to reduce stringing and leakage caused by long-distance idle movements and jumps.

- Some of PEI textured or PEI film build plates may exhibit excessive adhesion to TPU materials, making printed parts difficult to remove. It is recommended to use an uncoated steel plate with a small amount of PVP glue applied as the build surface.